Forming section

No matter what forming section! No matter what paper grade! No matter what machine! With Primoselect Heimbach offers you an innovative forming fabric, which combines optimum drainage with the best runability. The foundation for this is an innovative weave concept, which is unique on the market.

Primoselect paves the way for unexpected flexibility: the special weaving pattern allows options to suit your specific wishes. You can choose between:

- maximum dewatering capacity

- less energy consumption

- increased productivity

- longer lifetime

Press section

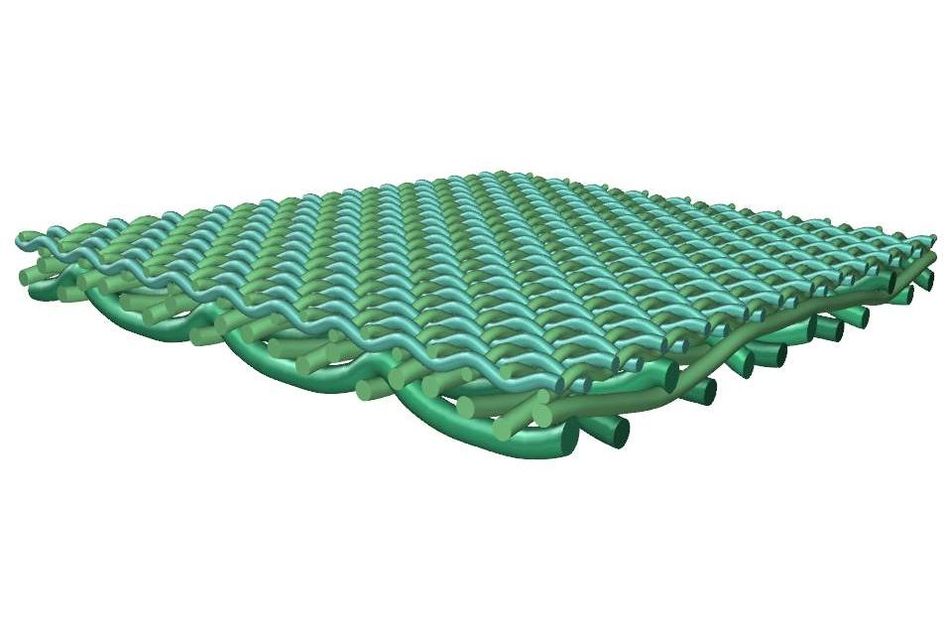

nonwoven

Multiaxial seam felt with compression layer and ONE strong seam

Features:

•High void volume

•High seam strength

•Moderate felt weight

•Easy installation (only one seam)

•Practically incompressible

•Resistant against shrinkage

•Excellent wear resistance

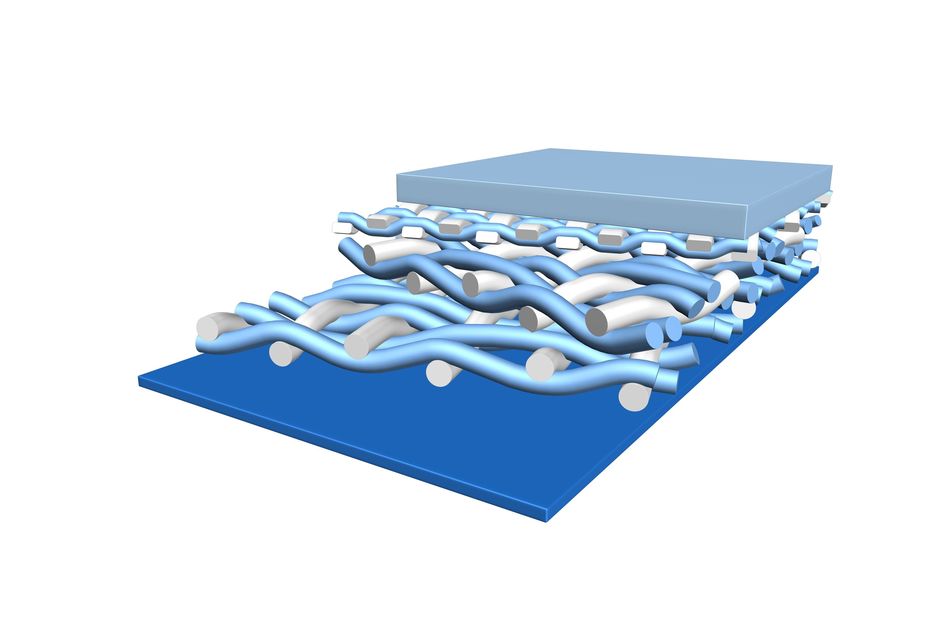

Atromaxx – the multiaxial module concept from Heimbach distinguishes itself by the selected combination of warp knitted and woven single base layers adapted to the specific demands of press configuration and paper grade. The wide range of combination possibilities provided by the modular construction technique enables fine adjustment to individual positions. Atromaxx is also available with seam.

Downloads

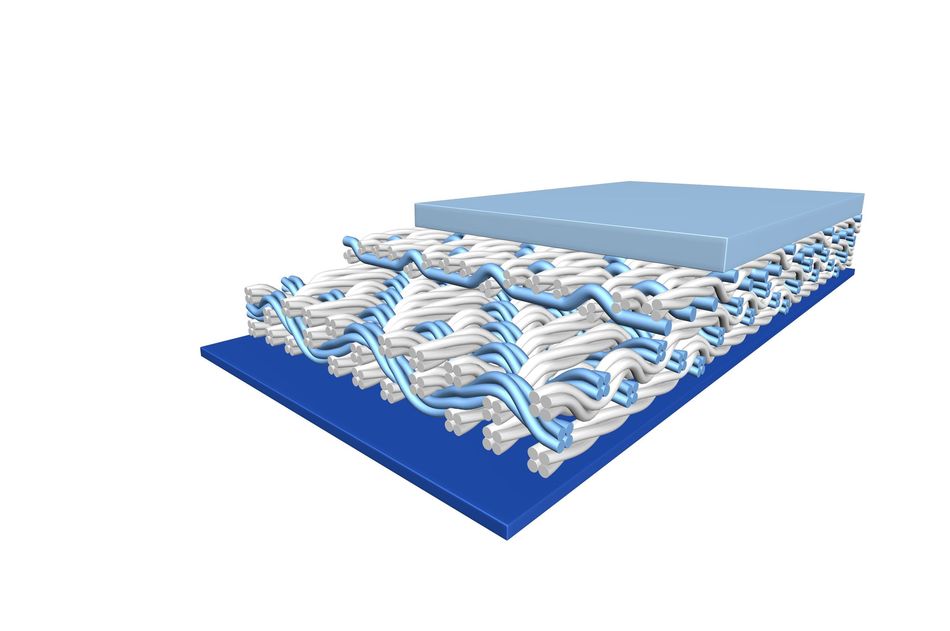

woven

Atroplan - woven press felt for all positions and press configurations. Ideal application for paper and board grades sensitive to marking, as well as for bulk print paper grades - for medium to high speed from Pick-up up to free standing presses. Atroplan is also available with seam.

High and continuous dimension stability; combination of single or multi layer base weaves for machines with the highest demands for handling large volumes of water and high press loads. Suitable for all paper grades.

Downloads