Forming section

No matter what forming section! No matter what paper grade! No matter what machine! With Primoselect Heimbach offers you an innovative forming fabric, which combines optimum drainage with the best runability. The foundation for this is an innovative weave concept, which is unique on the market.

Primoselect paves the way for unexpected flexibility: the special weaving pattern allows options to suit your specific wishes. You can choose between:

- maximum dewatering capacity

- less energy consumption

- increased productivity

- longer lifetime

Downloads

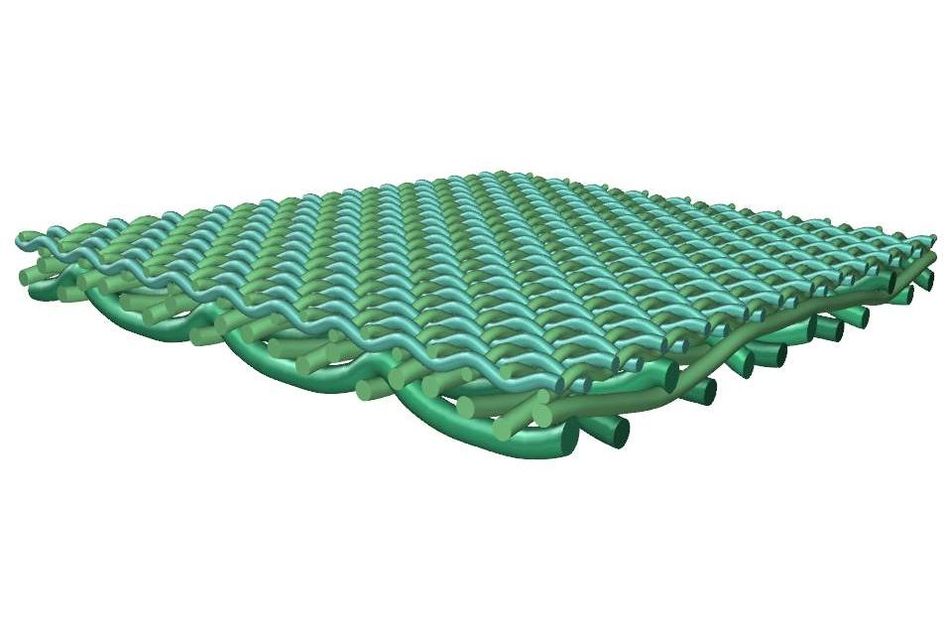

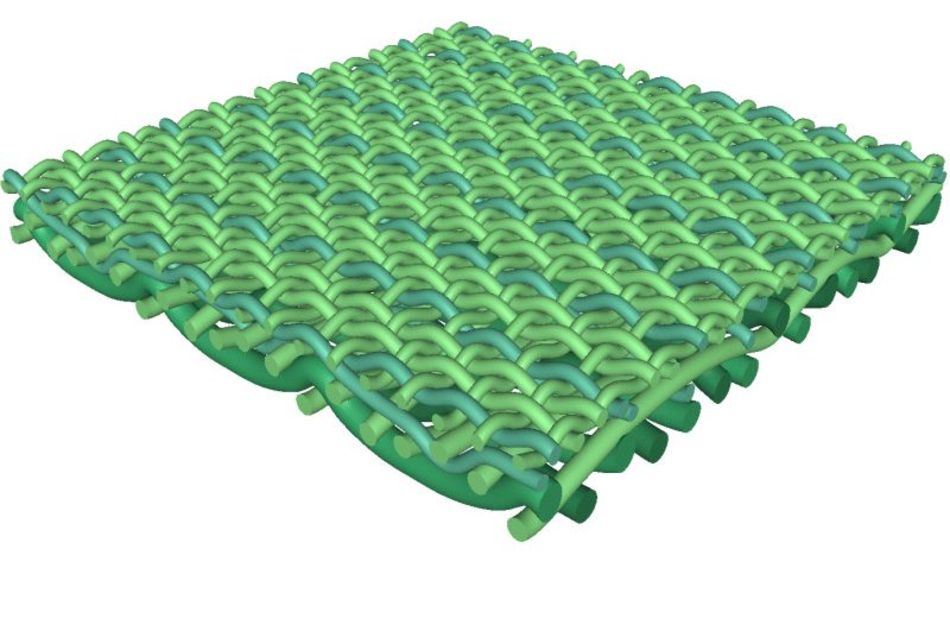

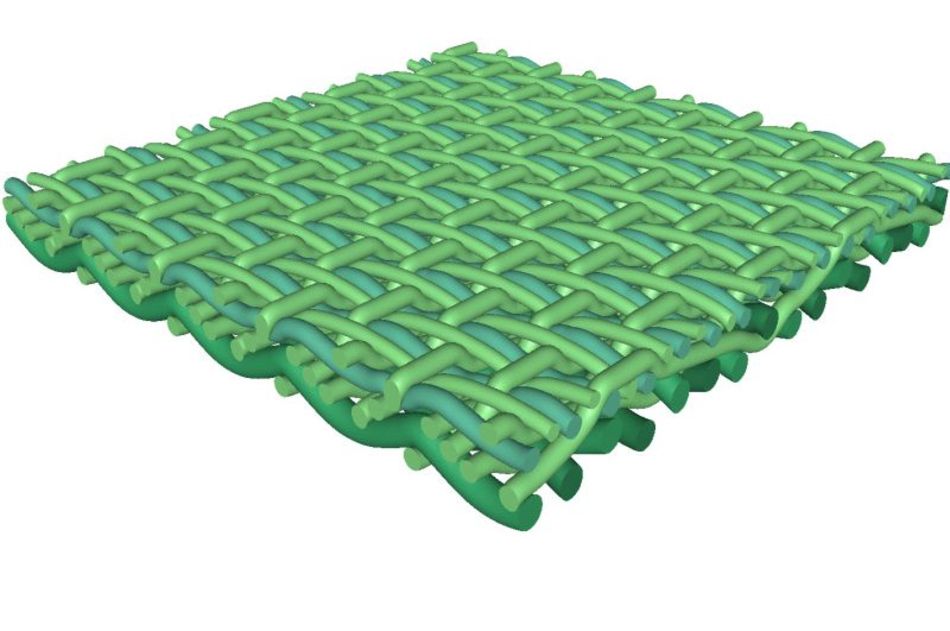

SSB forming fabric woven using 24 harness technology, which allows 6 shaft machine side construction to promote improved life potential. Available with 2 or 3 shaft paper side construction and 3:2, 2:1 or 1:1 weft ratio. Duralon, a patented machine-side weft material, is also available in Primobond designs to further improve life potential and reduce power consumption. The Primobond family has options in HD, F, SF or XF depending upon application or paper grade. The XF design benefits from Stabilon high modules machine direction yarns which promote high FSI without compromise to dimensional stability. A Primobond specification should be available to clothe all former types making all paper grades.

Double layer fabrics in 8- or 16- shaft construction with optional extra weft technology on the paper side. Duralon, the patented machine side weft material, is also available as an option to promote increased life potential and reduced energy consumption. Primoplan fabrics can clothe all former types making all papergrades.

Press section

nonwoven

Atrojet – Heading for new shores – with a perfect felt design

Atrojet is the unique press felt with a highly flexible, adaptable multiaxial non-woven module:

- Highly flexible and adaptable yarn content.

- Tailor-made felt designs – precise and uniform.

- Enables a variety of surfaces.

- Extremely fine or coarse open designs.

- High level of dewatering and uniform CD profiles.

- Improved void volume retention and efficient cleaning.

- High strength for an economic service life.

Atrojet.T – Fine-tuning for tissue

Tissue press felts are sophisticated products:

- High dewatering must be achieved at extremely fast running speeds.

- A new press felt has to reach optimal performance within just a few hours.

- Energy demand is a crucial factor for tissue producers.

- Tissue felts with their typical fine fibre batt laysers can pe prone to becoming prematurely dense and contaminated.

The tailored adaption and outstanding features of Atrojet press felts make them ideal for use in tissue production.

Downloads

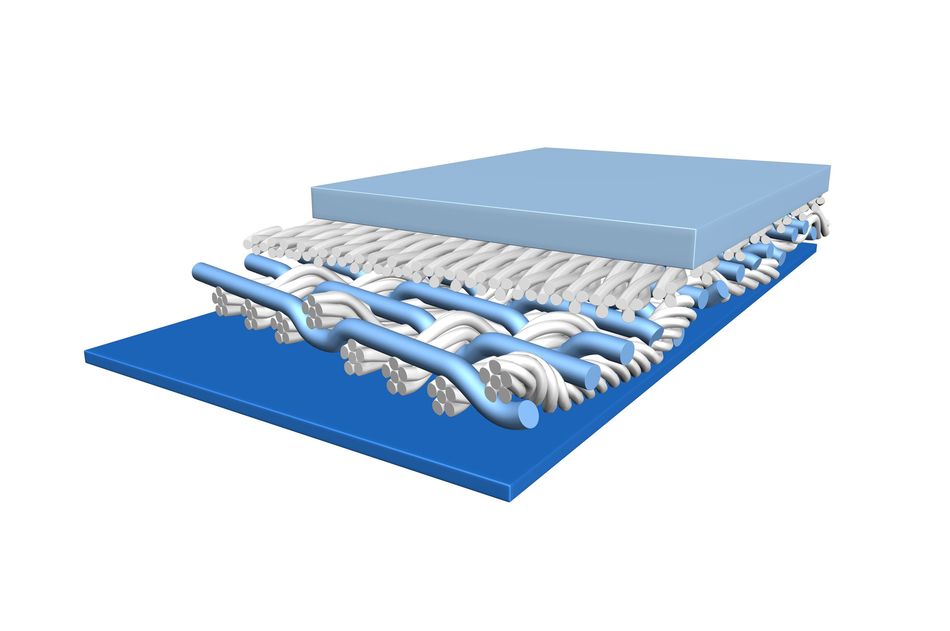

The base of Atrocross is composed of non-woven substrate layers positioned flat on top of one another both in the cross-direction and in the machine direction. The fast start and the good dewatering of Atrocross can be explained by the combination of three significant constructional features:

- The start-up density is virtually identical to the operating density.

- The paper-side CD yarns (“Micro Foils”) immediately scoop up high volumes of water into the inside of the felt.

- The roll-side MD yarns encourage rapid transfer of water through the felt.

Atrocross - non-woven technology for high-speed machines producing printing and writing paper grades - "the" standard for shoe presses. Different designs cater for different application requirements by adjustments to the modular structure / construction.

Downloads

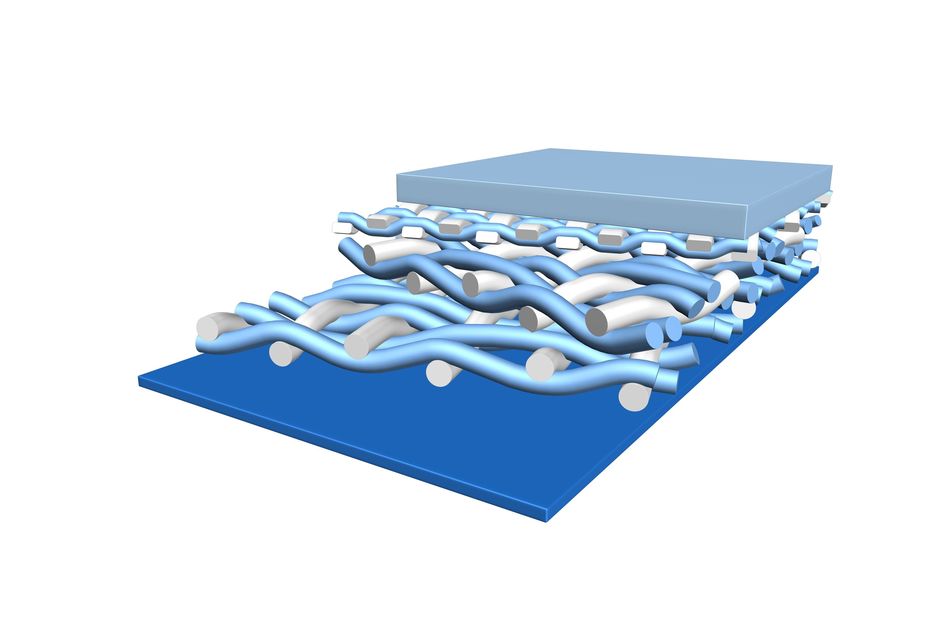

Atromaxx – the multiaxial module concept from Heimbach distinguishes itself by the selected combination of warp knitted and woven single base layers adapted to the specific demands of press configuration and paper grade. The wide range of combination possibilities provided by the modular construction technique enables fine adjustment to individual positions. Atromaxx is also available with seam.

Downloads

woven

Atroplan - woven press felt for all positions and press configurations. Ideal application for paper and board grades sensitive to marking, as well as for bulk print paper grades - for medium to high speed from Pick-up up to free standing presses. Atroplan is also available with seam.

Belts

High sheet dryness after the shoe press is a key factor to achieve a high machine speed and efficiency. Additionally, many paper quality parameters can be influenced by the shoe press concept and the shoe press belt technology. Most of the tissue shoe presses are equipped nowadays with press belts having continuous grooved designs. The combination and interaction of the advanced press felt (Atrojet.T / Atromaxx.T) and shoe press belt (Atrobelt) technology can be the key success factor, when the runnability of the paper machine are tuned to maximum efficiency. A major improvement of the new Atrobelt is superior mechanical resilience and void volume retentions which enable an effective dewatering and a higher life.

- Valuable selection of high-quality polyurethanes, unique embedded reinforcement structures.

- Smooth surfaces promote low flow resistance and provide efficient drainage for high dry contents.

- Excellent void volume retention of the groves.

- Increase mechanical strength and improve dimensional stability in machine direction.

- Highest resistance to cross machine direction and crack formation.

- Excellent resilience to chemicals and temperatures.

- Low hydrolysis to prevent swelling.

- Great stretching and recovery ability.

Transferbelts are a well established means for sheet transfer between press and dryer sections. In order to develop a new concept for transferbelts, Heimbach made use of the known strengths and weaknesses of products already in use in these positions and created the best possible design from that information.

Webmover can be described as a „transportbelt in the conventional sense without dewatering function“. Its patented porous, smooth surface with special topographical features guarantees trouble free sheet transfer, excellent sheet support and problem free sheet separation to the dryer section. Due to the very uniform material distribution in the cross section of the Webmover any water up take has minimal influence on its dimensions which provides the papermaker with extra security regarding runnability.

In general it can be said that the installation of transferbelts provides an ideal solution for the complete closing of open draws and the optimisation of sheet control.

Downloads